N12: Computational 3D Printed Textile

Continuum Fashion

2011

Collaboration with Jenna Fizel

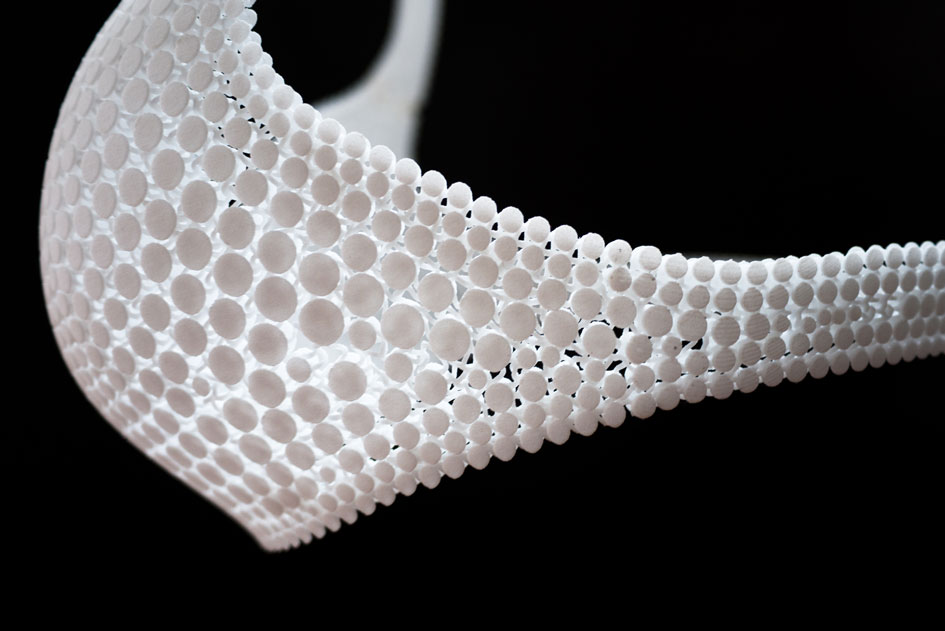

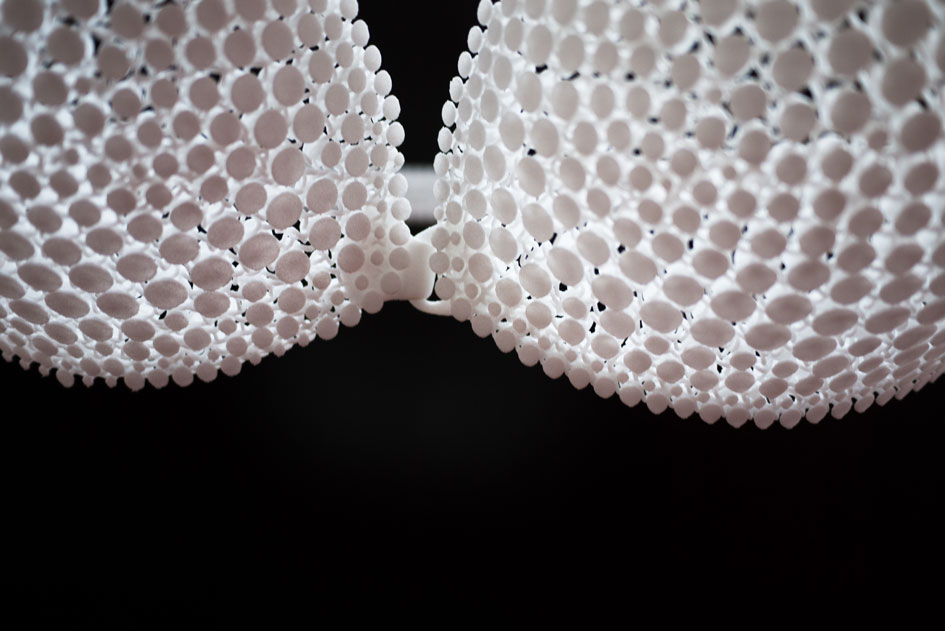

The N12 bikini is the world’s first ready-to-wear, completely 3D-printed article of clothing. All of the pieces, closures included, are made directly by 3D printing and snap together without any sewing. N12 represents the beginning of what is possible for the near future.

N12 is named for the material it’s made out of: Nylon 12. This solid nylon is created by the SLS 3D printing process. Its strength allows it to bend without breaking when printed very thin. With a minimum wall thickness of .7 mm, it is possible to make working springs and almost thread-like connections.

For a bikini, the nylon is beautifully functional because it is waterproof and remarkably comfortable when wet.

The bikini’s design fundamentally reflects the beautiful intricacy possible with 3D printing, as well as the technical challenges of creating a flexible surface out of the solid nylon.

Thousands of circular plates are connected by thin springs, creating a wholly new material that holds its form as well as being flexible. The layout of the circle pattern was achieved through custom written code that lays out the circles according to the curvature of the surface. In this way, the aesthetic design is completely derived from the structural design.